The Collection › Here |

||||

The history of the “Platen press” or “jobbing platen", as it was known of any machine that would print less than a full sheet of paper, dates back to Daniel Treadwell of Boston in 1818. Treadwell had experimented with various designs, and then followed George Clymer, the inventor of the Columbian, to England where he never fully completed and produced machines commercially. Another Bostonian, Stephen Ruggles, did complete a platen in 1839 and referred to as the Engine press. Later in 1851, Ruggles developments brought about the first vertical bed platen and laid the path for further breakthroughs. This came about through George Phineas Gordon, a New York printer, who in 1851, brought out the" Alligator". So nicknamed for the rapid closing of the platen and the amount of injuries and crushed fingers it caused. In Gordon’s system, the platen and bed moved together in a sort of arc with both the bed and platen coming to meet at impression but allowing for the platen to open almost horizontal for ease of feeding. It was said that Gordon, a spiritualist, had the concept come to him in a dream described to him by Benjamin Franklin. So Gordon named his first successful production press the “Franklin”. Patents were very important in the early years and although Gordon had a patent it was running out and would mean anyone could copy his design. This was how the “New Style” Gordon came about in 1872. Although this new press featured a “throw off”, it was not well received owing to a less attractive hinge-style platen and bed movement. Gordon presses, both new and old style, were eventually copied and many presses - some we have in our museum - were constructed. In 1901, the Chandler & Price Company of Cleveland purchased the Gordon business and C&P presses were still being manufactured up to the early 1970s. The modern Gordon platen is considered an American invention and quickly found favor on both sides of the Atlantic. English machines, like the ARAB and Cropper, owe much to George Gordon. The HIW also has a Westman & Baker Gordon, manufactured in Toronto. Further refinements of the platen led to such notable presses as the parallel impression Galley and Colts Armory, as well as the most popular of all platens - the Heidelberg Tiegel. Heidelberg’s T platen went on to become a fixture around the world and is still in demand.

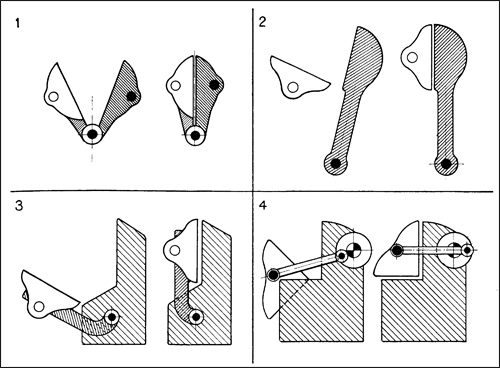

There are essentially four distinct Platen designs:  LIBERTY PRINCIPLE (Fig. 1) - a clamshell in a vertical “V” formation where both halves (platen & bed) close in an almost vertical orientation. The Liberty Job Press is an example. GORDON PRINCIPLE (Fig. 2) - the platen and bed work independently and swing in an arc meeting in an almost vertical position. Because of this independence, the platen is allowed to open in an almost horizontal position for ease of feeding. The Gordon and Chandler & Price is an example. BOSTON PRINCIPLE (Fig. 3) - the bed remains stationary and usually in a near vertical position. The platen moves in an arc to allow feeding and delivery. The Heidelberg T Platen and Golding Jobber is an example. GALLEY PRINCIPLE (Fig. 4) - similar to The Boston Principle, Galley is referred to as a parallel impression machine because the platen moves in a parallel arc to vertical bed. A gooseneck cam is used to orchestrate the opening and closing of the platen. This design remains popular for especially for embossing and die-cutting owing to its strength and ability to have enormous pressure applied. An example is the Galley and the Colts Armory. |

Letterpress is a method of printing using raised surface images and type. Machines, whether they are rotary, platen, hand or cylinder, developed from the uses of this method. Various countries varied the height of their type and this was the beginnings of standardization. Lead type could be made into a forme, and subsequently a locked chase would be placed in a bed of the machine.  Read more » |

|||

|

Printing Museum and Restoration |

800 Westgate Road Oakville, ON L6L 5N2 Tel. (905) 821-0000 Email: info@howardironworks.org Website: www.howardironworks.org |

- The Collection - Restoration - HIW Museum - Lease/Sales Program |

- Antique Books & Periodicals - About HIW - Volunteering Opportunities - Museum Shop |