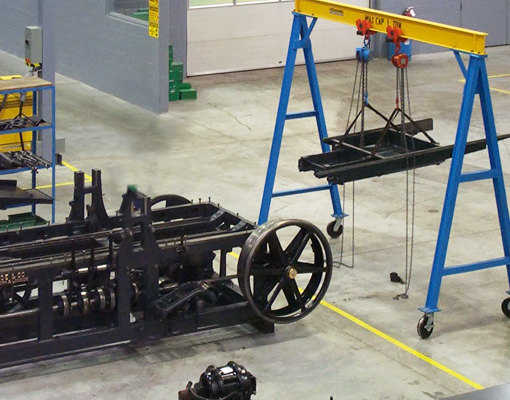

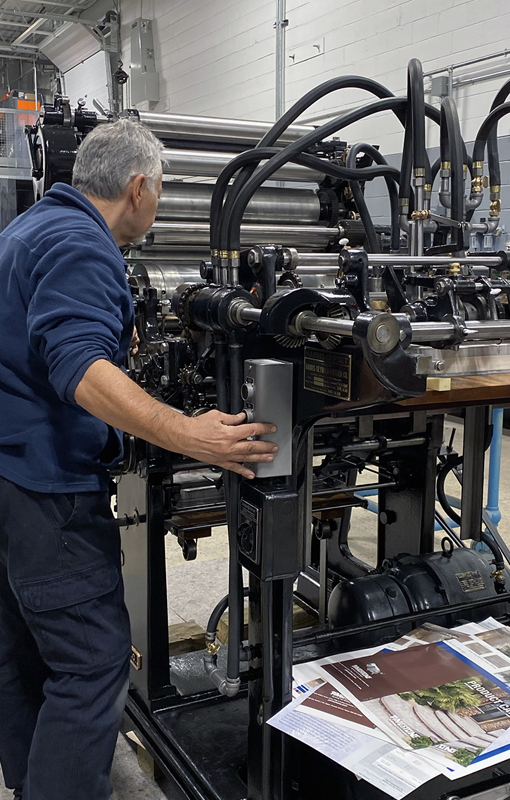

Behind each machine, there is a skilled group of individuals restoring them. We can think of no other industrial sector where one must have the skills of a machinist, the common sense of a millwright and the creativity of an artist. Each machine we undertake to restore starts with research. After which, the item is completely stripped and rebuilt.

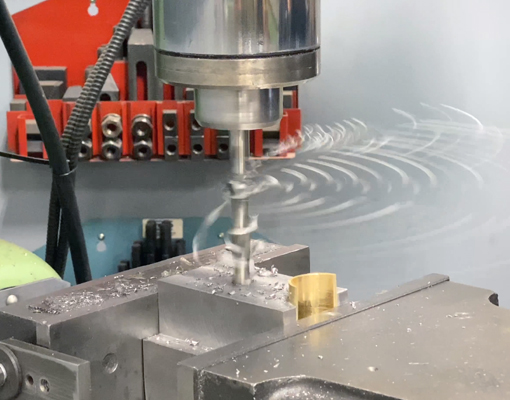

Almost all machines either need original items or have broken parts. In HIW's full machine shop, it’s our job to repair and remanufacture parts where there are rarely drawings. Everything from bed corners and friskets to finials and treadles are made right in the Works. The restoration work at HIW requires more than technical aptitude; it also involves a lot of ingenuity in rebuilding components from scratch.

Finishing and detailing are done by hand, echoing the excellent skills and creativity of the artisans from centuries ago. Processes include hand-engraving and hand-painting of intricate decorative features.

The ability of our people to research and reconstruct century-old machines sets HIW apart from most historical museums. On completion, all machines become fully functioning and as exquisite as the day they were made.

If requested, HIW offers our restoration services to others and will complete machines that can be purchased or leased for use or as beautiful displays.

For inquiries about our restoration services, please get in touch with info@howardironworks.org.

GO TO THE GALLERY »